Tool breakage detection function by camera

Quickly checks the status of the tool before and after tool change

Cleaning achieved by coolant with 20 μm filtration accuracy at the time of tool exchange

Ensures no chip on tool clamping

20 μm filtration accuracy achieved by three stages of the cyclone filter

Sludge associated with the aluminium machining is removed

| Axes | |

|---|---|

| X, Y, Z-axes | 560 x 640 x 640 mm |

| Table | |

| Distance from pallet top to spindle center | 80 720 mm |

| Distance from pallet center to spindle end | 70 710 mm |

| Pallet working area | 400 x 400 mm |

| Maximum work piece size | Ø 630 x 900 mm |

| Maximum pallet load | 400 kg |

| Pallet surface configuration | 20 - M16 tapped |

| Spindle | |

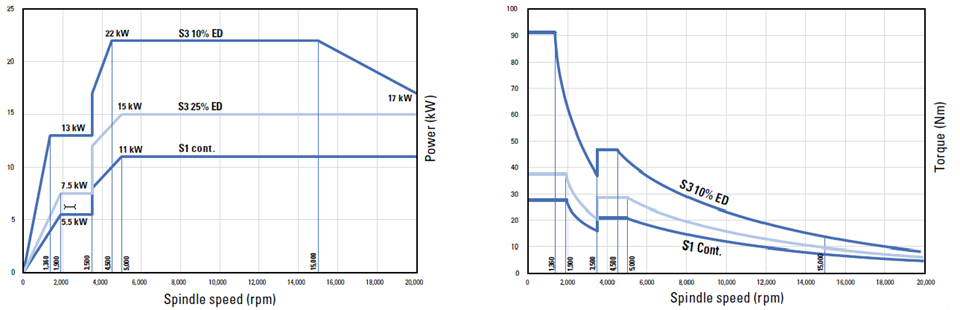

| Spindle speed range | 50 20,000 rpm |

| Spindle taper | HSK-A63 |

| Spindle bearing ID / OD | Ø 70 / 110 mm |

| Spindle power characteristics | 22 / 15 / 11 kW (10% ED / 25% ED / cont.) |

| Spindle torque characteristics | 91.3 / 37.7 / 27.6 Nm (10% ED / 25% ED / cont.) |

| Spindle acceleration time | 1.5 sec |

| Feedrate | |

| Rapid traverse | 60,000 mm/min |

| Cutting feed | 1 60,000 mm/min |

| Automatic tool changer | |

| Tool storage capacity | 60 |

| Max. tool diameter (without / with limitation) | 70 / 170 mm |

| Max. tool length | 360 mm |

| Max. tool weight | 8 kg |

| Max. tool moment | 11.76 Nm |

| Machine size | |

| Machine height | 2,503 mm |

| Machine footprint (width x depth) | 2,424 x 4,249 mm |

| Maintenance floorspace (width x length) | 3,745 x 4,662 mm |

| Machine weight | 6,000 kg |