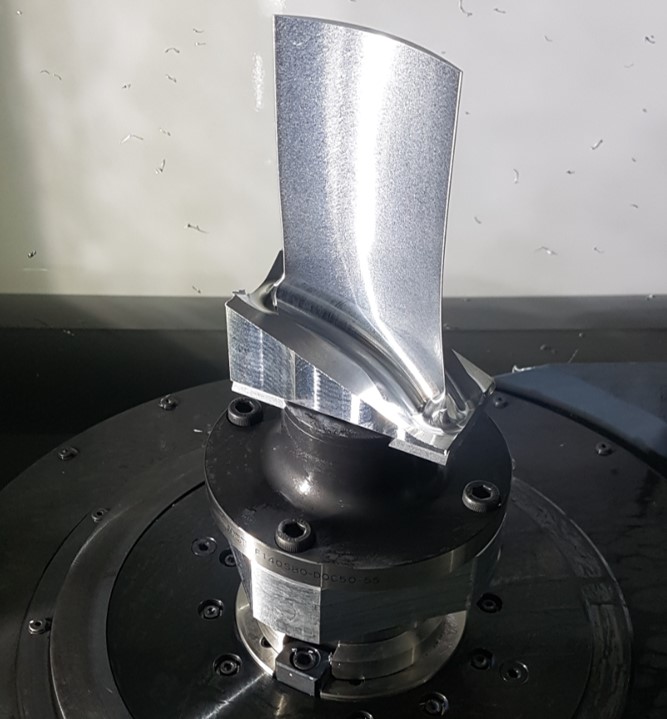

Outlet guide vane in the motorThe outlet guide vane (OGV) has two different purposes:

These two functions put a lot of stress on OGVs, which are normally very thick and have complex shapes in order to meet these two requirements. Depending on the engine, the materials and shapes change significantly. |

|

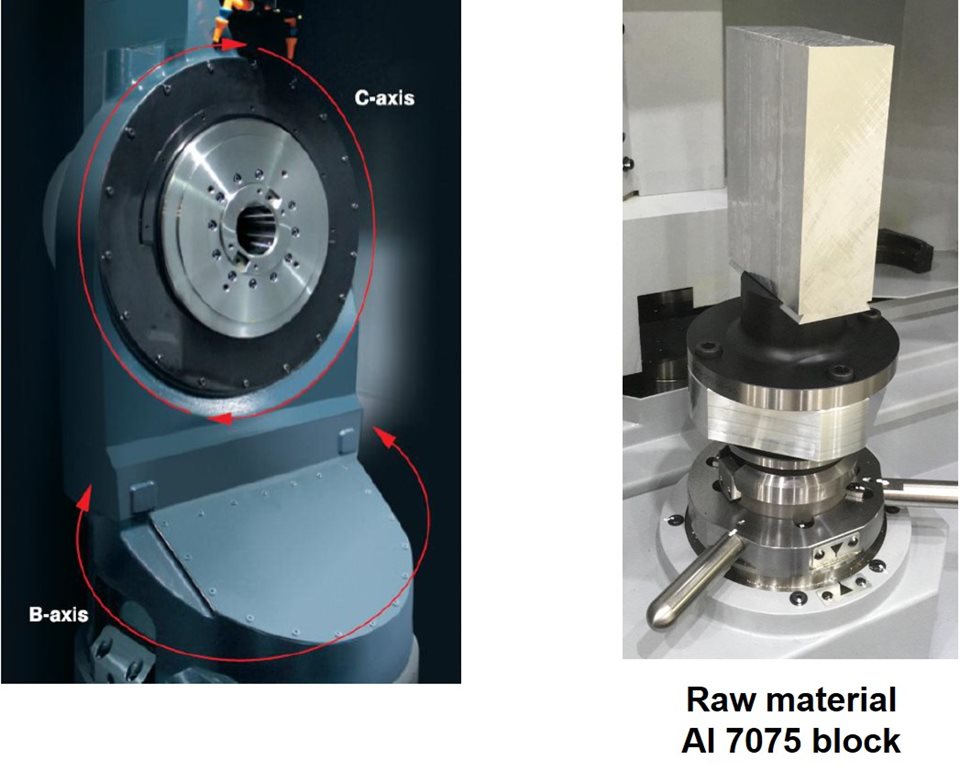

ProcessThe part was roughed and finished with a single Ø20mm toric end mill in just one operation using sequential machining:

This machine’s rigidity and high dynamics allowed us to achieve a high-quality surface. |