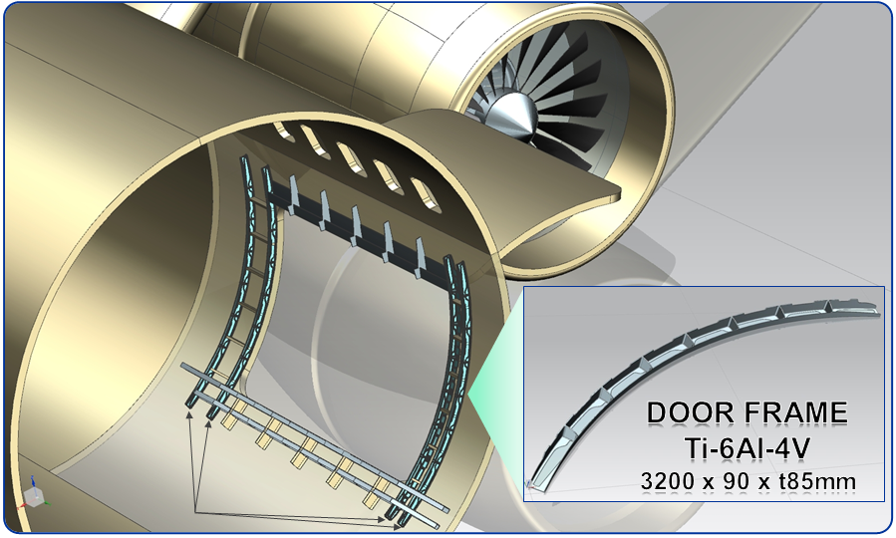

WIn this particular case the customer was unsure whether a T1 or T2 machine would be better. From the parts’ package in question some, like the door frame, were T4 parts, but most of the other parts were suitable for both a T1 and a T2.

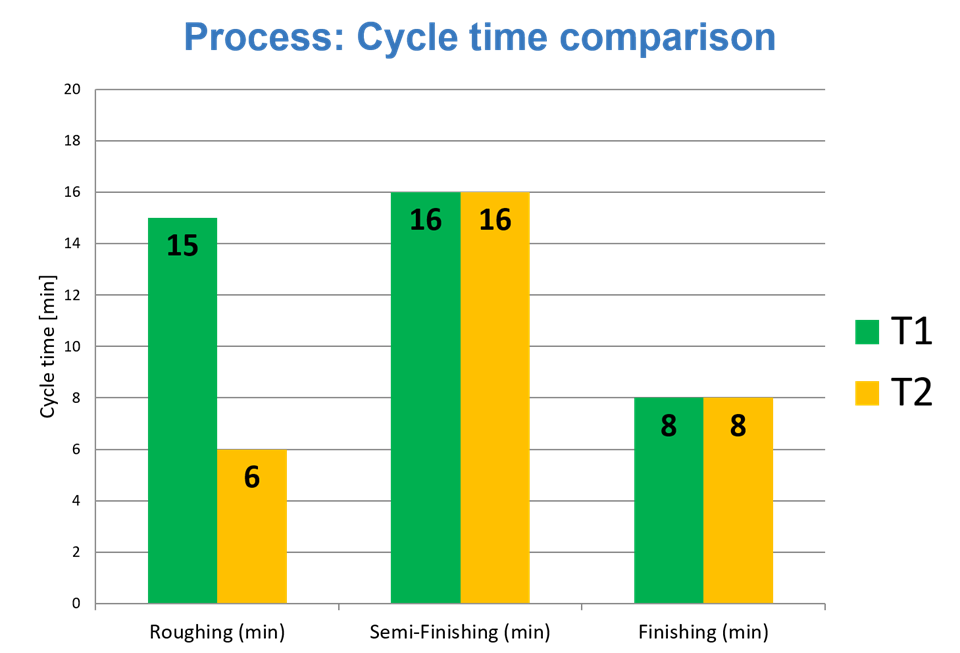

As the process was not set, we were absolutely free to test when to use a T1 and when a T2.

After machining the part, the answer was pretty much clear to this customer.

The results showed a similar performance from both machines in terms of finishing and semi-finishing (when spindle was not fully loaded), but in roughing the advantage was clear.

T1: 15 minutes

T2: 6 minutes

The additional 500 Nm T2 can deliver makes all the difference in the final part.

When to use which machine?

- Starting from a block: T2

- Starting from a precise forging with very few radii: T1

- Starting from a rough forging or with lots of radii: T2