Serial production in die & mould marketThe die and mould market has always been a very traditional production. Hand polishing, manual setting, manual probing, etc.The tendency is changing. Now manufacturers want to go into fully automated systems. The traditional machines are not able to sustain this production and the five axis machines are becoming more popular to finish the part completely and get a better surface quality. The example of the electrical connector is a proof that this type of machining is possible. |

|

|

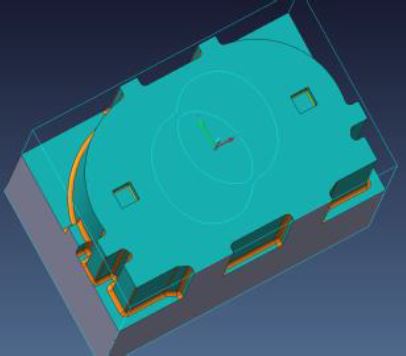

Our caseWe wanted to demonstrate one possibility of how a die and mould automation could be, so we featured the production of an electrical connector.The first operation of the part is to produce the shape of the connector. For this purpose, we used a D200Z, which we equipped with the 100 tools extension magazine to add it additional autonomy for the automated production. In this operation we use the 5 axis capabilities of the machine to use shorter tools and: 1) Extend tool life 2) Improve surface quality After milling the part has to go to a sinking EDM process, in our case we did with an EDAF2 machine. Here we produce the sliding guides on the side of the punch and the squared shaped on top. In order to automate it, we use an Erowa Compact robot to feed both machines minimizing the layout Results:

|