The right solution for difficult parts

| Size | Ø16 x 30 mm |

| Material | 1.2083 (52HRC) |

| Machining Time | 5 hours 55 min |

| Tools | Five tools of Five kinds |

| Surface roughness Ra | 17 - 24 nm |

| Size | 10 x 10 x 10 mm |

| Material | Binder-less carbide |

| Machining Time | 14 hours 22 min |

| Tools | Four tools of Three kinds |

| Surface roughness Ra | 0.59 nm |

.jpg.aspx?width=1329&height=886&ext=.jpg&maxsidesize=960&resizemode=force)

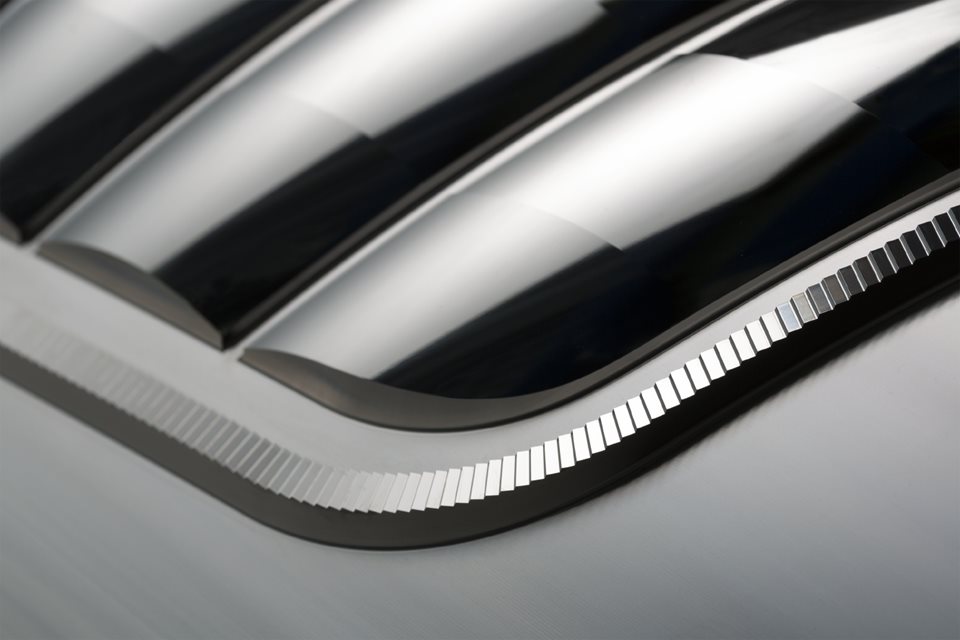

| Size | 390 x 200 x 180 mm |

| Material | Pre-harden (40HRC) |

| Machining Time | 93 hours 33 min |

| Tools | 17 tools of 14 kinds |

| Surface roughness Ra | 30 nm |