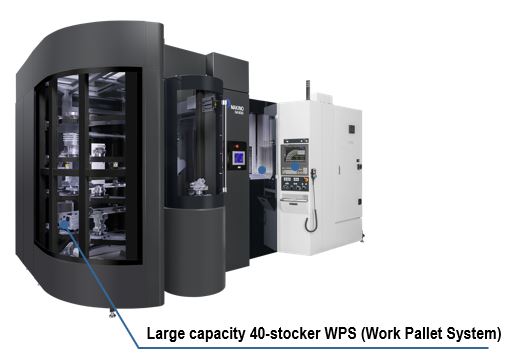

Maximize your profitability with the integrated automation of this 5-axis vertical machining center. Reduce cycle time and increase productivity with a 40-pallet system, a unique polygonal tapper pallet, a high-capacity integrated tool magazine, and an easy-to-use pallet management system.

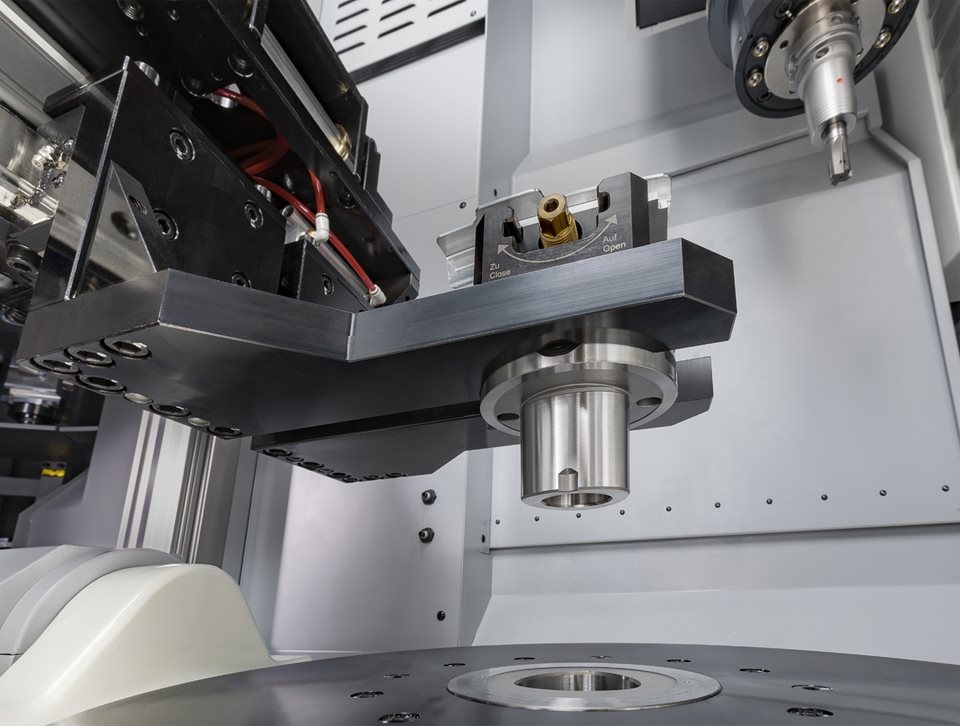

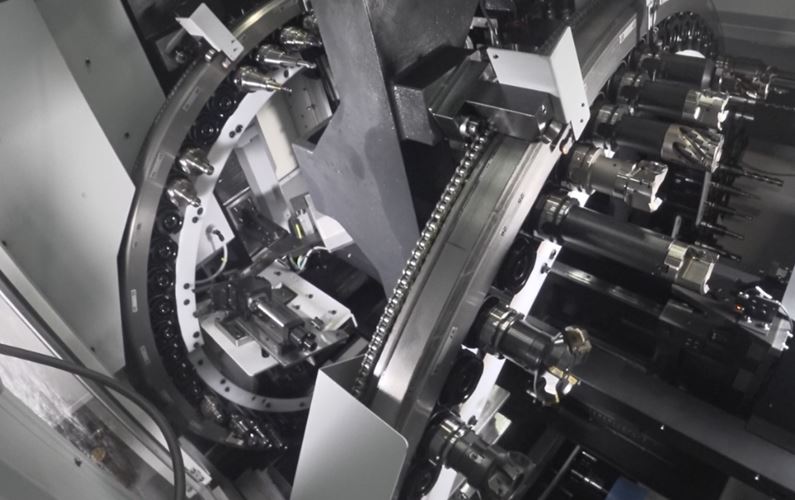

Large capacity 118-tool magazine is attached.

A double ring magazine system using a highly reliable ring magazine has been adopted.

All WPS-related management and operations can be performed on this single screen. It is not necessary to switch back and forth between the LCD on the WSS (Work Setting Station) page and the NC screen to perform an operation or confirmation. The status of pallet placement of 8 pieces pcs x 5 steps can be seen at a glance. In addition to easily capturing the status of "ready", "finished", "pending", etc., the interface is also intuitive in displaying machining orders, delivery orders, etc. It has all the functions needed on the shop floor, such as interruptions for express work.