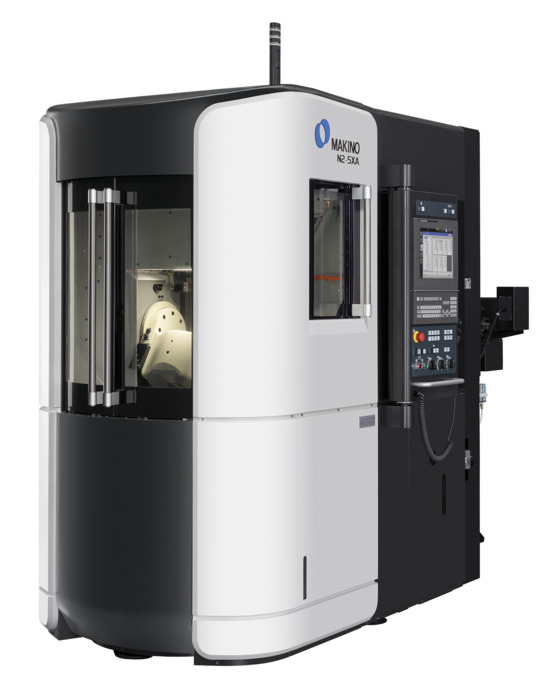

Makino has launched the N2-5XA, a 5-axis horizontal machining centre engineered to revolutionise medical implant production. Its unique design avoids the use of water-based coolant by deploying a unique chip-less design of the machining chamber. Thanks to the Professional 6 NC control unit and the direct-drive rotary axes the N2-5XA is capable of producing components with the smoothest possible surfaces.

The N2-5XA is engineered to offer the best performance in its machine size category – without using cutting oil lubrication. Especially designed for use in the medical manufacturing industry, e.g. for femoral knee implants, the N2-5XA exceeds the quality demands for medical use and ensures sustainable performance. Without cutting oil lubrication and thus without coolant, the simplified machining process helps end-users to reduce tack times, which in return enables higher production quantities.

Smooth surfaces are of utmost significance, particularly for medical implants. To deliver the surface finish the parts need, the N2-5XA is a 5-axis machining centre featuring a trunnion table equipped with direct-drive motors on both the B and C axes. The small trunnion structure and long rotary travels grant the flexibility to access any part from any position. And thus offer full flexibility, not only for implant production.

The most demanding implants can be cut on the N2-5XA without cutting oil lubrication. By avoiding the use of coolant, this machine is more environment-friendly. Besides, not using coolant brings the additional benefit of cost savings in production additives. The machine structure of the N2-5XA with its almost vertical walls and scraper allows effortless chip evacuation. This also reduces the removal, cleaning and maintenance time and minimises the machine’s overall downtimes.

For cutting processes where cutting fluid is mandatory, the machine can be equipped with a coolant tank, nozzles on the spindle and machining area and, optionally, a through-spindle coolant for up to 15 bar

The 20,000 HSK-A40 spindle opens up the possibility of roughing and finishing implants on the same machine. The new machining processes and minimum run-out ensure a unique smoothness of the final part.

The N2-5XA can be deployed in an automated production environment. The front door allows for robot loading. The possibility of installing two hydraulic lines at 70 bar and one air line allowing the installation of fixtures for automatic operation.

The N2-5XA features a fully equipped Professional 6 control unit. The smoothing functions of the NC control unit help to achieve the highest quality surface finishes. As a standard feature, a collision-safe guard is installed on all Makino machining centres to avoid collisions involving workpieces, tools and fixtures.