The Slim3n three-axis vertical machining center is a powerful, space-saving solution for turnkey and automated machining of components and parts. Suitable for both single-machine applications and as part of a multi-machine installation in a high-volume, low-mix production environment, the Slim3n expands Makino's portfolio of machines that are at the heart of its turnkey and automated solutions for market sectors such as automotive, die casting, medical and others.

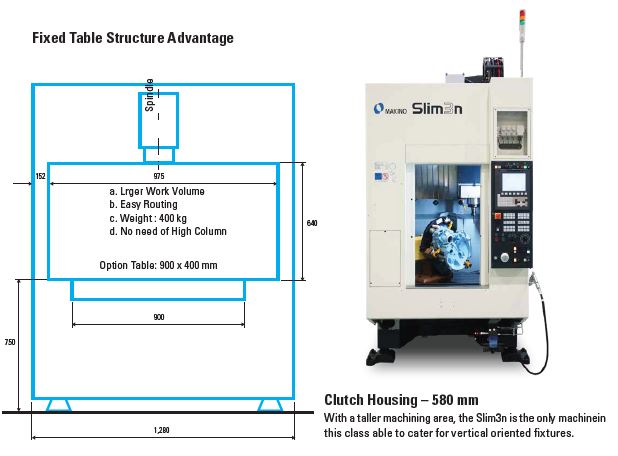

Slim3n series is equipped with optional interfaces provided to meet the demands of the high volume production environment. With its capability to accommodate larger workpiece and fixture (measuring up to 975 x 500 x 580 mm with 400 kg payload), the Slim3n series gives higher value for money to the customers.

The Makino Slim3n can be configured with an integrated, automatic pallet changer (APC) with a 550 x 380 mm pallet and a 4.5-second pallet change time. It can also integrate with a wide assortment of material handling systems, from manual operator transfer to automatic transfer featuring conveyors and loaders to unattended gantry and robotic systems.