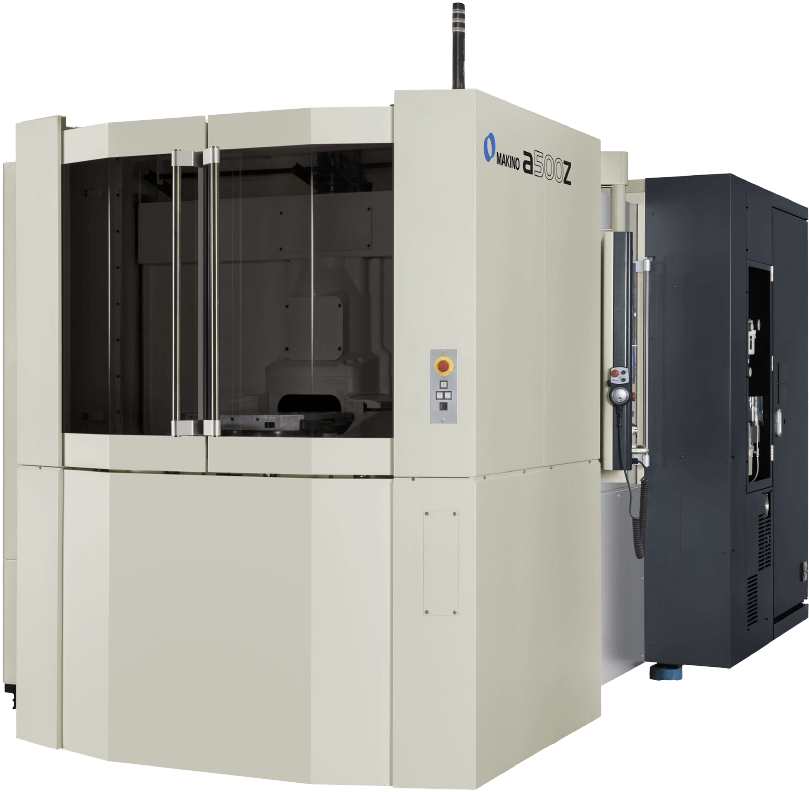

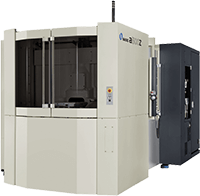

Pallet:

a500iR

Built for high-efficiency machining of small to medium, complex parts like monolithic aerospace components. The a500iR’s unique pallet changer ensures superior chip-shedding and ergonomic loading with upright machining and vertical pallet positioning.

_low.png.aspx?width=634&height=650&ext=.png&maxsidesize=960&resizemode=force)