.jpg.aspx?width=800&height=605&ext=.jpg&maxsidesize=960&resizemode=force)

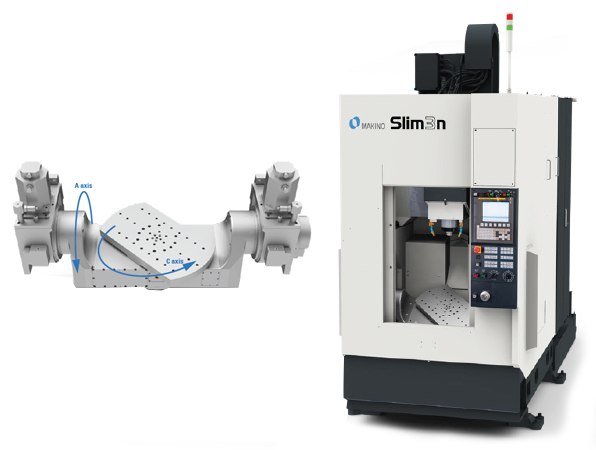

Slim3n adopts fixed table design to provide customer flexibility for fixture design to meet demands of larger envelope, higher fixture weight and simple interfacing that allows a wide range of machining applications.

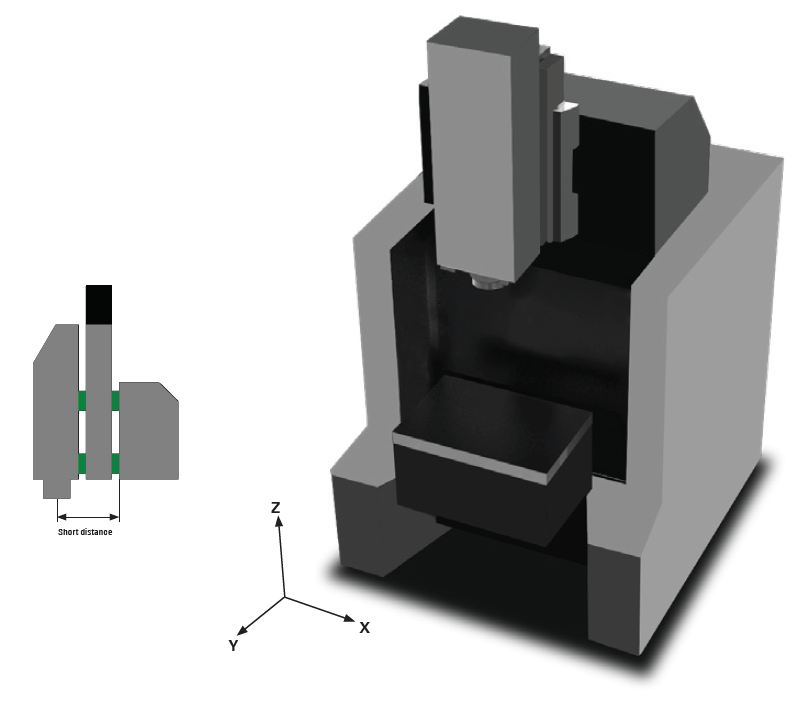

Finite Element Analysis (FEA) design techniques were employed to optimize structural rigidity and torsional stiffness for ultimate performance and consistent results. The machine structural configuration is based on a closed frame type design together with a pair of long supporting columns achieving superior structural rigidity.

Makino machines are known for achieving accuracy through mechanical means with both design & manufacturing process.

The short spindle overhang directly influences the structural force loop distance, which increases the structure’s overall torsional stiffness about X axis. This characteristic is designed to increase major natural frequencies of the system. Consequently, enhances the cutting performance on Slim3n.

Standard 26 tool ATC magazine, the Slim3n provides smooth, fast indexing to support high speed machining application. Designed with an armless, direct tool pick for increased performance, it also has an integral door design adding benefits of no separate actuators making it more reliable.

Makino’s leadership in spindle technology is renowned throughout the world. Spindle rigidity, higher speed, constant pre-load, multi-plane balancing, minimum vibration and reduced thermal growth are key topics that Makino has pioneered through the art of spindle making by innovative design and manufacturing.

The Slim3n comes with 2 spindle specifications 16,000 rpm and 8,000 rpm to cater to the varying machining applications for high volume production machinery industry demands.

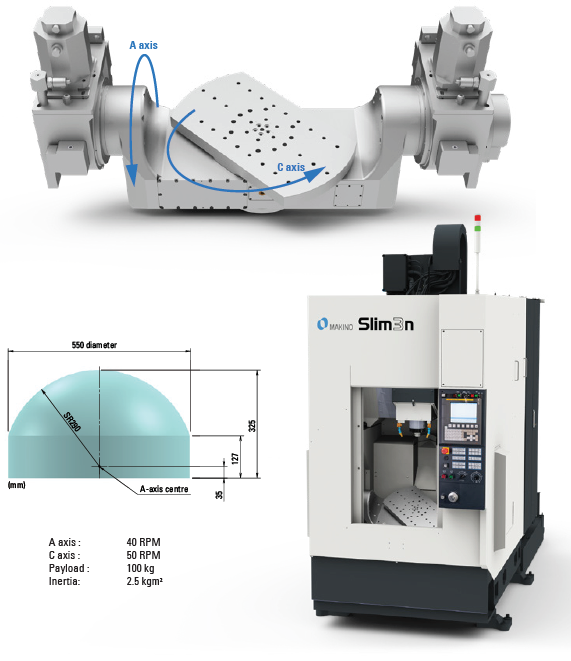

For Large Workpiece machining of 4+1 Axis application using two synchronized motors

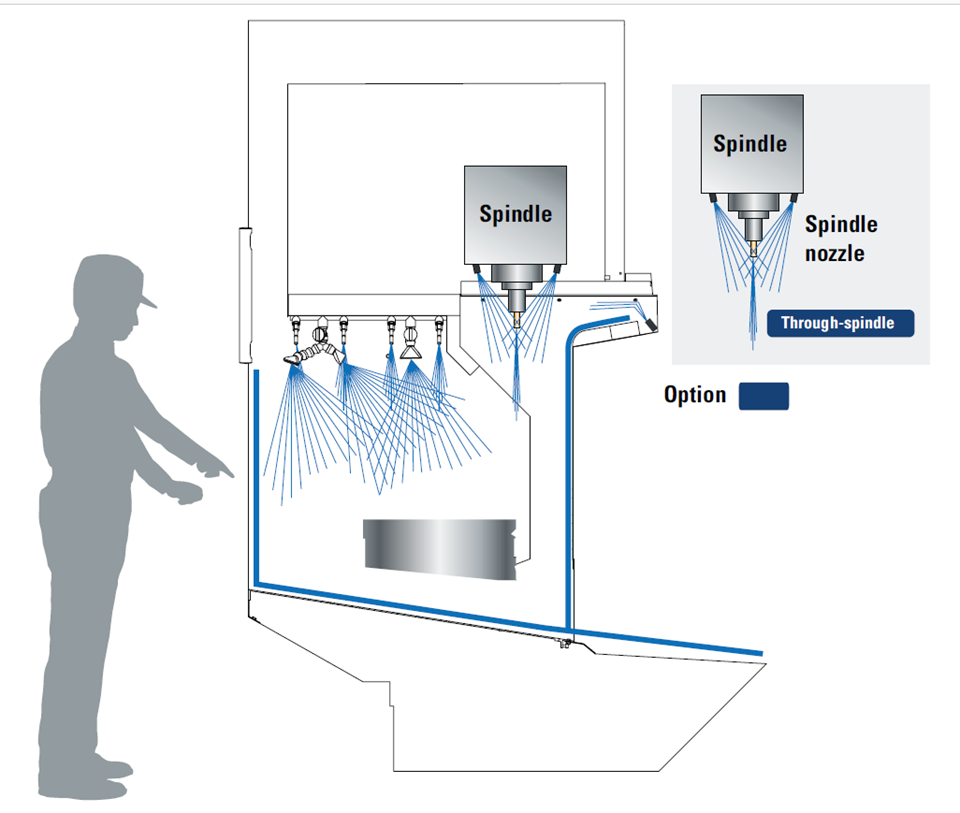

Created for the production environment, Slim3n coolant system enhances the productivity. Configured with nozzle and flush coolant as standard features, chips are efficiently removed from the cutting zone. Slim3n structure is designed with a slope for quicker evacuation. A Lift Up Chip Conveyor option can be integrated at the rear of the machine to tailor to high chip generation demands.

Improves the machining process more effectively especially with deep hole drilling operations and provides increased tool life.

| Travel | |

|---|---|

| X x Y x Z | 500x400x500 |

| Rapid | 50,0000 |

| Cutting | 1 20,000 |

| Spindle | |

| Spindle RPM | 16,000 (optional 8,000) |

| Spindle Taper | HSK - A50 |

| Feedrate | |

| Rapid Traverse | 50,000 mm/min |

| Cutting Feedrate | 1 - 20,000 mm/min |

| Table | |

| Maximum Workpiece | 975 x 500 x 580 mm |

| Maximum Payload | 400 kg |

| Automatic tool changer | |

| ATC Capacity | 26 |

| Tool Diameter/Length | 140/320 mm |

| Table | |

| Tool Tool Weight/Tool Moment | 3.5/2.4 |

| Coolant Tank | |

| Tank Capacity | 400 L |

| Total Flow Rate | 150 L/min |

| Machine | |

| Floor Space - Std./APC | 1,280x3,650 mm/1,455 x 4,120 mm |

| Height | 2,940 mm |

| Weight - Std./APC | 4,700 Kg/5,050 Kg |